B elow is an overview of how insulated precast foundation affects modular homes construction.

elow is an overview of how insulated precast foundation affects modular homes construction.

Construction of Modular Homes

A modular home uses conventional stick framing and must satisfy the same building codes as a site-built home, and holds its value about as well. Modules are built in a factory and finished on the inside. They’re trucked to the site and set in place with a crane. The local builder knits them together and adds finishing touches, like decks.

Modular homes come in all quality levels and price points, and some manufacturers combine custom-built modules in different ways to create complex designs.

In principle, the factory environment, where sections for modular homes are produced, offers better control over everything from the framing to the insulation, but in reality the product varies. The quality offered by some modular builders can equal site-built homes and some firms have designed “green” modular homes.

Insulated Precast Foundation

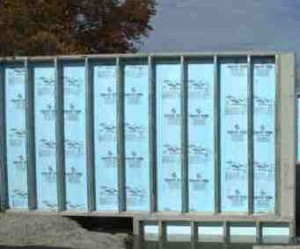

An insulated precast foundation panel is a sandwich of rigid foam insulation between oriented strand board that results in a structural panel. Precast foundation panels come with pre-cut window and door openings as well as conduit for electrical wiring. They’re used for walls and ceilings, and can be combined to create nearly any home design. Specially trained crews assemble them on the jobsite. They’re often used to cover a traditional timber frame, or post-and-beam structure, but they can also be self-supporting.

A modular home with insulated precast panels tends to be well insulated and draft free, so it needs less energy to heat and cool than a typical stick frame. As such, you may need a smaller heating and cooling system.

While the materials for the building shell will cost more than a wood frame, builders who offer this system claim that overall cost roughly equals stick framing, and may even be lower. That’s because it takes less labor to assemble the panels, and the insulation is already in place.

In case you still have questions about modular homes, you may contact Legendary Homes Inc in Jackson, Michigan. A representative will be happy to assist you. Meanwhile, you can check our modular home price sheets by signing up to our blog.