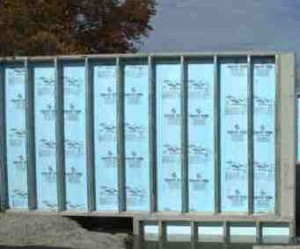

Insulated precast foundation has been used to enhance the quality of a modular home or any structure. Its design has also received appreciation from both the contractors and homeowners. The exterior surface of precast foundation can vary from an exposed aggregate finish that is highly ornamental to a form face finish that is similar to cast-in-place. Some precast panels act as column covers while others extend over several floors in height and incorporate window openings.

Insulated precast foundation has been used to enhance the quality of a modular home or any structure. Its design has also received appreciation from both the contractors and homeowners. The exterior surface of precast foundation can vary from an exposed aggregate finish that is highly ornamental to a form face finish that is similar to cast-in-place. Some precast panels act as column covers while others extend over several floors in height and incorporate window openings.

In most cases, the architect selects the cladding material of an insulated precast foundation for appearance, provides details for weatherproofing, and specifies performance criteria. The structural engineer designs the structure to hold the cladding, designates connection points, and evaluates the effects of structural movement on the cladding. The precast concrete manufacturer designs the cladding for the specified loads, erection loads, connection details, and provides for the weatherproofing, performance and durability of the cladding itself.

Insulated precast foundation wall systems offer a wide variety of shapes, colors, textures, and finishes to the designer. As a result, the assessment of samples is a key component in the use of precast concrete. The majority of the review and approval process is conducted at the precast plant prior to precast panel production. This assessment is in addition to the quality control and field testing that takes place during the production phase.

Typically, each insulated precast foundation panel is independently supported to the building structure using an assemblage of metal components and anchors. Joints around each of the precast panels are usually filled with sealant.

Structural Aspects of Insulated Precast Foundation Design

Precast foundation wall systems are most often constructed as a curtain wall or veneer, in which no building loads are transferred to the concrete panels. Most typically the insulated precast foundation wall system must resist lateral loads directly imparted on it, such as from wind and earthquake; as well as vertical loads resulting from the self weight of the precast wall system. These loads must be transmitted through the wall system and secondary structural elements to the building’s structure. Other loads such as erection, impact, construction related, and transportation must also be taken into account in the design. It is important to evaluate the design, detailing and erection of precast panels in order to avoid imposing unwanted loads onto the panels.

Joints between panels must be wide enough to accommodate thermal expansion and differential movements between panels. Joints between panels are most commonly sealed with sealant to prevent water penetration in the wall cavity. The wall cavity space and back up wall which is usually covered with a water resistant membrane provide a secondary line of protection against water penetration into the building.

The concrete panels are designed in accordance with PCI Design Handbook-Precast and Prestressed Concrete (MNL 120), Design Responsibility for Architectural Precast Concrete Projects (ACI 533.1R-02), and ACI 318 Structural Concrete Building Code. Steel elements of a wall system are designed in accordance with AISC specifications for steel construction. Precast concrete elements are designed in accordance with ACI and PCI specifications.

Application of the Insulated Precast Foundation Design

Precast concrete wall systems allow a wide variety of colors, finishes and architectural shapes. Precast concrete can be used in environments that allow the use of conventional cast-in-place concrete. In addition, precast concrete may be made in a controlled environment and erected in an environment that would not allow site casting of concrete. The concrete used in precast panels should be designed to be durable in the environment in which it will be used.

In case you still have question about modular homes and insulated precast foundation, you may contact Legendary Homes Inc in Jackson, Michigan. A representative will be happy to assist you. Meanwhile you can check our modular home price sheets by signing up to our blog

The type of construction affects how an insulated precast foundation may be damaged, cracked, settled, or moved. Each type of precast foundation, however, has their own unique characteristics and provide certain number of benefits.

The type of construction affects how an insulated precast foundation may be damaged, cracked, settled, or moved. Each type of precast foundation, however, has their own unique characteristics and provide certain number of benefits.